01

Solid connection

POLBLAT production boards are made of properly seasoned and selected high quality wood, offered by the leading wood producer in Poland.

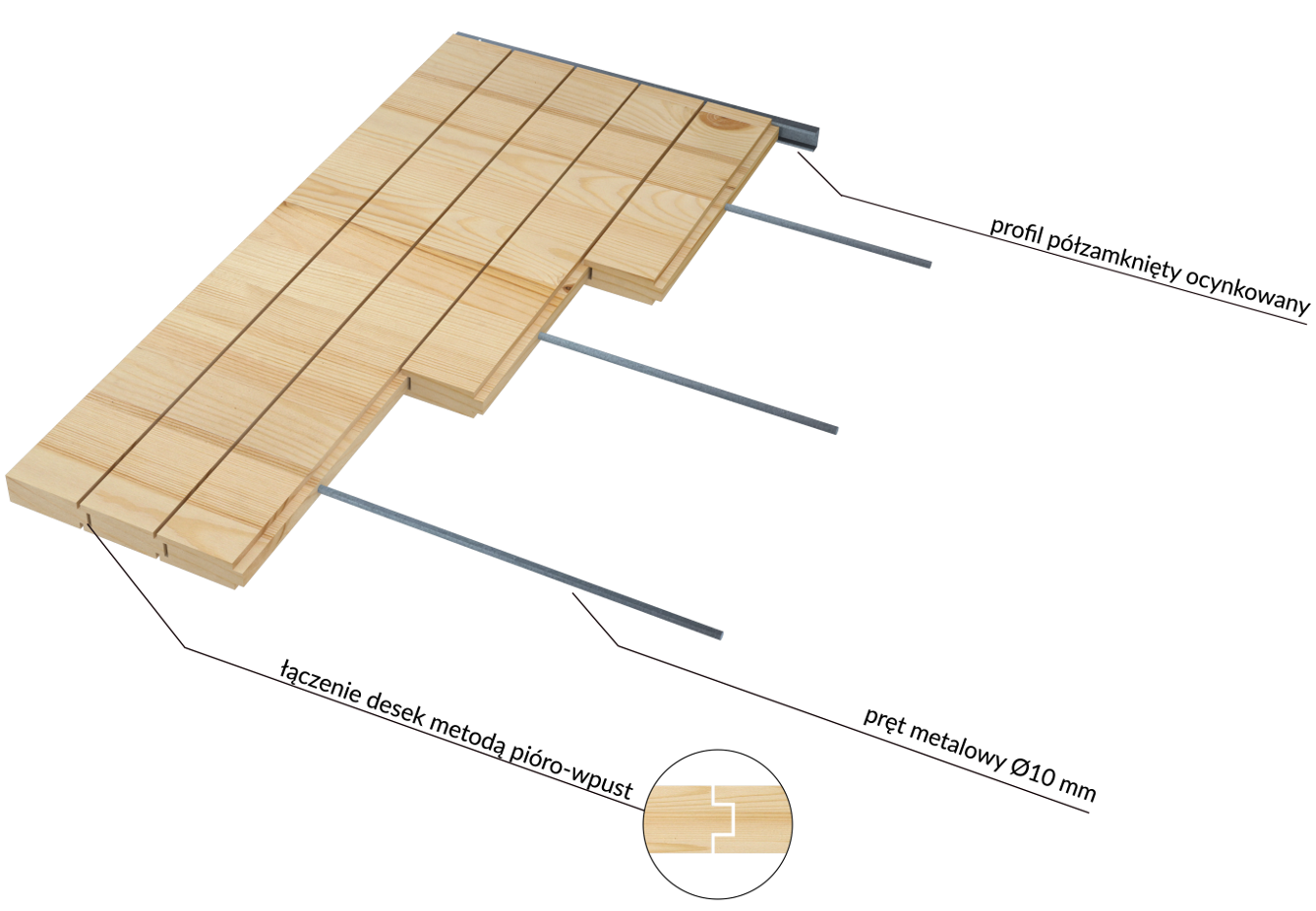

After delivering wood and checking humidity, boards are made by joining individual slabs with a tongue and groove method. Thanks to this method, vibrations from concrete block machines are better transferred to a concrete mix, which directly affects the quality of manufactured products.

To ensure high durability of the boards they are additionally twisted together with bars of precisely chosen hardness and thickness (10mm). The rods pierce the whole board along its entire length in three appropriately designed distances. Better stiffness of the boards is associated with a smaller deflection arrow as well as the possibility of producing heavier precast concrete products.